STANDARD SHACKLE MOUNT

$172.00

- 25,OOO LB CAPACITY (MINIMUM BREAKING STRENGTH)

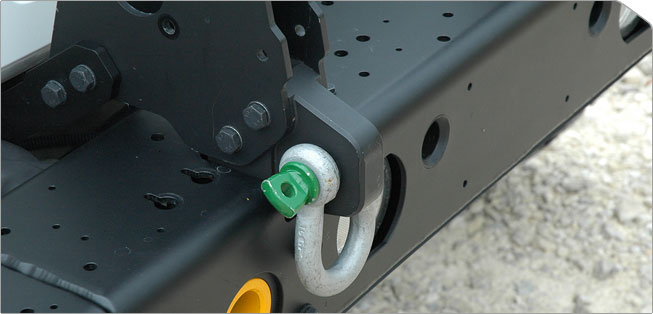

- ACCEPTS MOST 3/4” RECOVERY SHACKLES

- LEFT & RIGHT MOUNTING

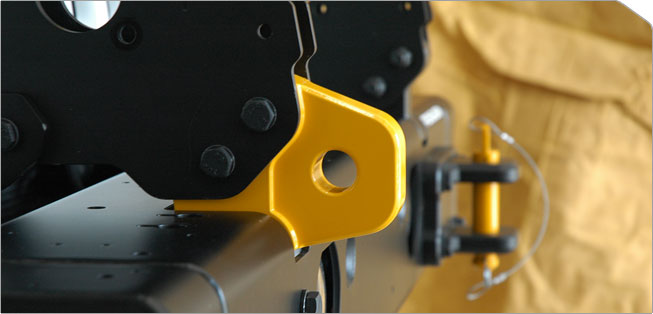

- BLACK OR YELLOW OPTIONS

- LIGHTWEIGHT / HIGH-STRENGTH

- 6O61-T6 ALUMINUM CONSTRUCTION

- 2-STAGE POWDER COATING

![]()

MFES-O72O

Out of stock

Off-road and expedition vehicles are going to use recovery gear. Period. And you’re going to need a place to safely and securely attach that recovery gear. With that in mind we designed our MFES Standard Shackle Mounts. These mounts (single or dual options) provide strong, secure and safe mounting points for standard 3/4” recovery shackles.When you stop and look at the forces involved in your standard off-road recovery scenario you quickly realize that this is one area where things can get dangerous very quickly if parts fail. Our 1 1/8” thick Standard Shackle Mounts are rated at 25,000 lbs (minimum breaking strength) and are CNC machined from 6061-T6 aluminum billet, providing high-strength, light weight and rust proof performance. For severe duty applications you can also outfit the MFES with single or dual Rotator Shackle Mounts (45,000 lb minimum breaking strength).

Most shackle mounts present a problem when not being used in the fact that they must, by design, protrude from the body of the front-end system. This presents large snag point for obstacles (logs, rocks, etc.) you may be trying to drive or skid over. This is made worse on many bumper systems by the fact that the shackle mounts are positioned low or even underneath the bumper, providing even more snag interference.

A low or under-bumper position of a shackle mount also makes access to the shackle mount even more difficult when the vehicle is in deep mud, sand or snow. In this case you will find yourself having to dig for your shackle mount just to attached the recovery strap. This can also be a problem in steep approach angle scenarios where you front bumper may be jammed against the opposite face of a deep ravine. In this case getting to a low mounted shackle mount will be extremely difficult.

The MFES Standard Shackle Mounts are positioned above the bumper body which eliminates snag interference in technical driving scenarios. This high position also provides easy shackle access in all but the worst deep mud, sand or snow recoveries. This high mounting position also greatly reduces than chance of a trapped or pinned shackle in steep approach angle scenarios.

MFES models (except C1 models) come standard with a single Standard Shackle Mount and second Standard Shackle Mount can be added if desired (C1 models use Recovery Hooks and optional Rotator Shackle Mounts). The Standard Shackle Mount can be mounted on either the left or right upper assembly or both sides if dual mounts are required (see photos above).

The MFES Dual Standard Shackle Mounts are 2-stage powder coated and available in matte black or recovery yellow. Fasteners are grade 8.8 and OE-grade triple coated for maximum corrosion protection (1000+ hr salt spray test).

- High-Strength / Lightweight / No Rust Performance

- CNC 6061-T6 Aluminum Construction

- 25,000 lb Capacity (Minimum Breaking Strength)

- High-Mount, High-Clearance Design

- Accepts Most 3/4” Recovery Shackles

- Left & Right Mounting Locations

- 2-Stage Powder Coating – Black or Yellow

- Triple Coated Grade 8.8 Fasteners

- US-Made

- Not for C1 Models

Outfitting your vehicle for off-road and expedition work comes down to selecting the right gear for the specific terrain and task at hand. When we designed the MFES-JK we weren’t just redesigning the traditional front-end system, but also redesigning how people are better able to use their off-road gear. In addition to lightweight and high-strength performance we have added a new level of functionality to off-road equipment in the form of numerous accessories and tools that change the standard front bumper into a full function accessory mounting system for the Jeep JK. We let you choose the accessories and tools you need for your off-road and expedition efforts. In addition to these accessories we also offer a full line of Recovery and Winch Gear options.

Front Skid Plate

For additional underbody protection we designed our dual-plate, all-aluminum, Front Skid Plate. This design uses a 3/16” 6061-T6 aluminum primary skid plate that joins the MFES-JK to the Jeep JK factory impact beam. We then added a secondary 3/16” layer to the design, also 6061-T6 aluminum, to provide additional impact protection and durability.

Aluminum construction ensures lightweight and rust-proof performance and both skid plate components receive a 2-stage matte black powder coating. All fasteners are grade 8.8 and OE-grade triple coated for maximum corrosion protection (1000+ hr salt spray test).

Hi Lift Shackle

The Hi Lift jack is a highly effectively off-road and expedition tool. It can also be highly dangerous as the jack has a bad habit of wanting to slip out from under the vehicle during lifting. Our Hi Lift Shackle removes this danger by providing a secure, no-slip, fully pivoting mounting point for the Hi Lift jack that still allows the jack to align properly to the load without jamming or damaging the bumper. Or the user. The MFES-JK includes dedicated Hi Lift jack cutouts in the bumper structure, but even with these jacking points the jack can become trapped by the bumper structure if the vehicle tips, causing damage to the bumper body and the coating.

The Hi Lift Shackle mounts in two dedicated mounting points on the MFES-JK outer sections (stub and standard width) and can be used in the two GearMount mounting points as well, giving you four mounting point options on the MFES-JK. It will also work with our Modular Rear Bumper System (MRBS) and side rail systems. CNC machined from 7075 T-6 aluminum. Rated at 12,000 lb MBS.

Splash Guards

Our optional Splash Guards for the MFES-JK are designed to reduce water, mud and rocks being thrown forward from your tires onto the MFES-JK outers. The guards fill the gap between the outer section of the MFES-JK and the factory Jeep fenders. They have been tested and designed to provide a maximum balance of performance and protection without adding unneeded material. The Splash Guards are cut from 3/16” 6061-T6 aluminum and are 2-stage powder coated in matte black. Fasteners are grade 8.8 and OE-grade triple coated for maximum corrosion protection (1000+ hr salt spray test).

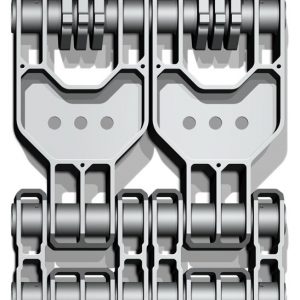

Traction Cleats

In some off-road and expedition scenarios you may be working in heavy mud (think Camel Trophy) or the challenge may be snow and ice. In either case you can find that climbing up on the front bumper can be a risky maneuver with the chances being fairly good that you either slip off the bumper or find yourself face down on the hood of the vehicle. For our friends in these environments we have designed our Tractions Cleats. Unlike diamond plate or grip tape, which quickly become useless is mud and snow/ice scenarios, the Traction Cleats are aggressive aluminum cleats that bolt on to the upper surface of the MFES providing a secure, non-slip, foothold in the worst conditions. The Traction Cleats attach at 12-14 pre-drilled locations on the upper surface of the MFES-JK. Each cleat is cut from 6061 aluminum and 2-staged powder coated to match the MFES-JK. The Traction Cleat kit comes with 4 Traction Cleats and associated fasteners (triple coated).

GearMount™ Accessory Mounting System

Off-road and expedition vehicles are all about gear and cargo and how to move them safely and easily. Our innovative GearMount accessory mounting system allows you to quickly and securely improve the gear and cargo capacity of your Jeep JK by giving you the ability to transform your MFES into a high-strength, high performance gear and cargo platform. Our system consists of two dedicated mounting hardpoints that allow you to easily attach a variety of off-road and expedition components ranging from cargo racks to winches to work tables. Whatever you need is easily and securely attached to the MFES-JK, as well as our Modular Rear Bumper System.Unlike traditional receiver hitch mounted designs, our patent pending, dual mounting point locking system gives you a stronger and more stable accessory mount that allows you to attach or remove an accessory in under three minutes. Our design also removes all free play from the mounting. All of this innovation translates directly into more load capacity and durability in rough terrain.

The MFES Standard Shackle Mount is designed for use in medium to heavy-duty recovery applications where proper recovery techniques are used. Extreme angle recoveries (far left or right of the vehicle centerline) place extreme loads on rigid recovery mounting points and can cause component failures. Recovery shackles are not designed for extreme side loading and their strength is reduced dramatically in such scenarios (see shackle manufacturer websites for details). For severe duty and extreme side loading applications see our Rotator Shackle Mounts.

The MFES Dual Standard Shackle Mounts are constructed from CNC machined 6061-T6 aluminum billet. This rust-proof, high-strength, lightweight material provides excellent strength and performance. In addition, the aluminum construction provides a rust-proof structure, which is critical for long term durability for a component designed to endure frequent impacts and abrasions that will damage and remove protective coatings.

Our all aluminum design requires no coating to withstand rust and we could ship them uncoated without issue. However, we provide a 2-stage powder coating to match the MFES. We offer the Dual Standard Shackle Mounts in both matte black (to match MFES) or recovery yellow. Powder coating will be chipped and scratched in the off-road environment. This cosmetic damage can be touched up with paint or left untreated as desired.

To ensure high-strength performance we use all grade 8.8 fasteners on the MFES Dual Standard Shackle Mounts. These are treated with a 3-stage OE-grade coating for maximum corrosion protection (1,000+ hr salt spray test certification).

- Does not fit C1 and C1-S configurations

Materials

- 6061-T6 Aluminum

- CNC Machined

Powder Coating and Protection

- Corrosion Resistant Aluminum Construction

- 2-Stage Powder Coating

- Triple Coated Grade 8.8 Fasteners

Vehicle

- All Pronghorn front-end and rear-end systems

Required Tools and Materials:

- The MFES-JK is a No Cut / No Drill installation. To efficiently complete the installation of your MFES-JK you will need the following tools and materials, in addition to those parts supplied with your MFES-JK.

Tools

- 7mm Socket (and suitable ratchet)

- 10mm Socket (and suitable ratchet)

- 17mm Socket (and suitable ratchet)

- 19mm Socket (and suitable ratchet)

- Phillips and standard screwdrivers

- 7mm Wrench (box/open)

- 10mm Wrench (box/open)

- 17mm Wrench (box/open)

- 19mm Wrench (box/open)

Materials

- Masking Tape

- Touch-up Paint (for vehicle frame if required)

MFES-JK Install Guides:

Manufacturer: Pronghorn Overland Gear

Model Number:MFES-JK-O72O

Download and print out the Accessory Products Guide

Related products

-

LinkTrac LXP

$185.00 – $740.00 Select options -

HI-LIFT SHACKLE

$95.00 Read more -

TRACTION CLEATS

$35.70 Read more -

RECOVERY HOOKS

$137.00 Read more